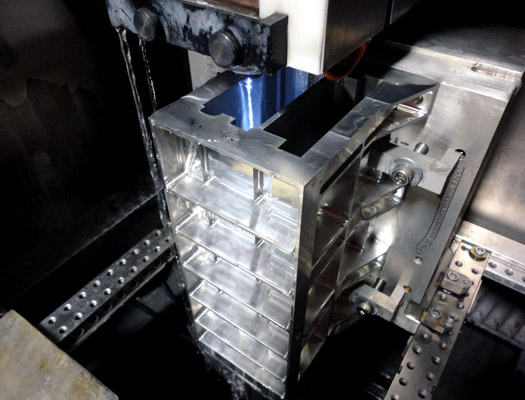

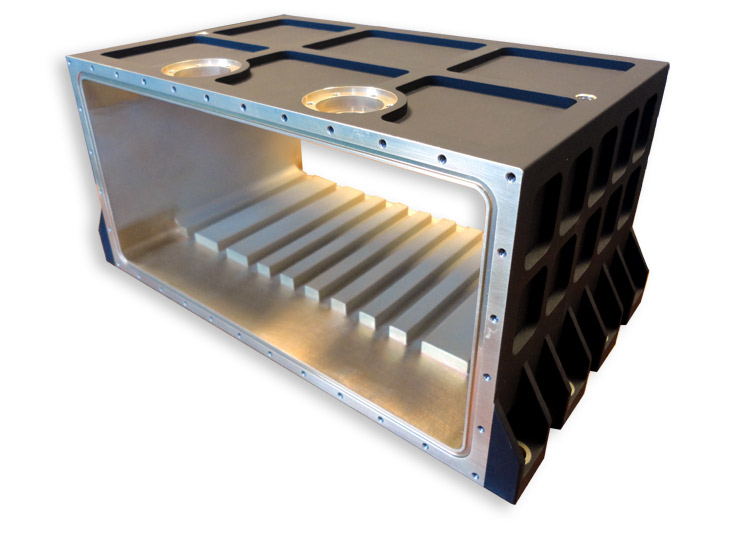

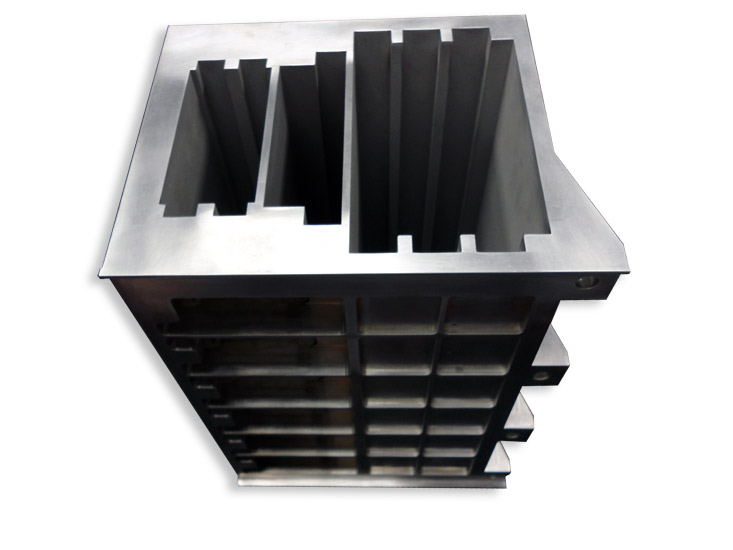

G&Z has been able to produce some very interesting electronics chassis with a mixture of CNC Milling and Wire EDM.

Wire EDM is a method to cut conductive material with a thin wire. Wire diameters range from .004" - .012" although small and larger diameters are available. There is no physical contact with the wire and the part. Rather, the wire is charged to a voltage very rapidly. It's the electrical charge or spark that is actually cutting the material.

Most Wire EDM equipment can independently move on (4) axis to generate taper cuts. This process is mainly used in cutting die or extrusion molds. Wire EDM can be accurate to +/- .0001" with no burrs because there is no actual cutting force against the material. G&Z has the ability to cut up to 16" thick material in our Wire EDM department.