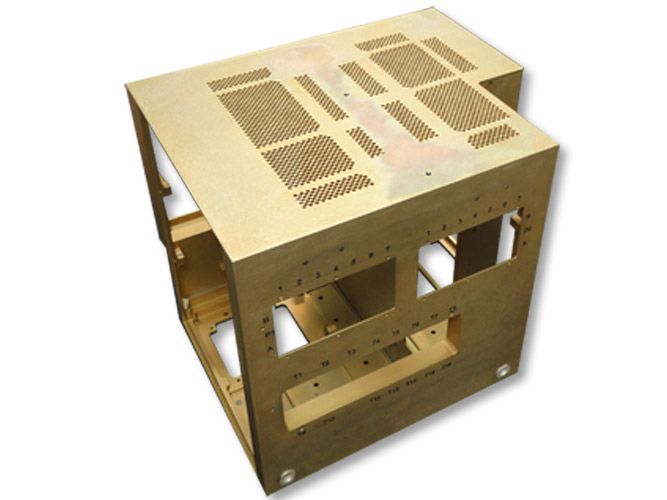

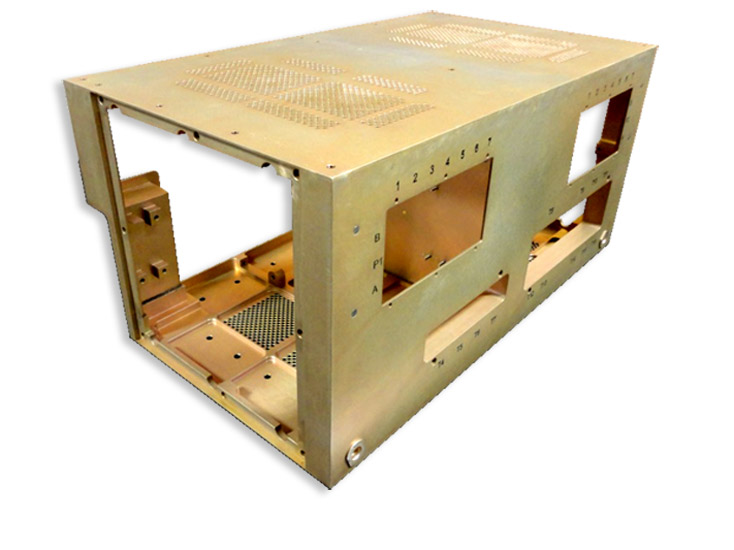

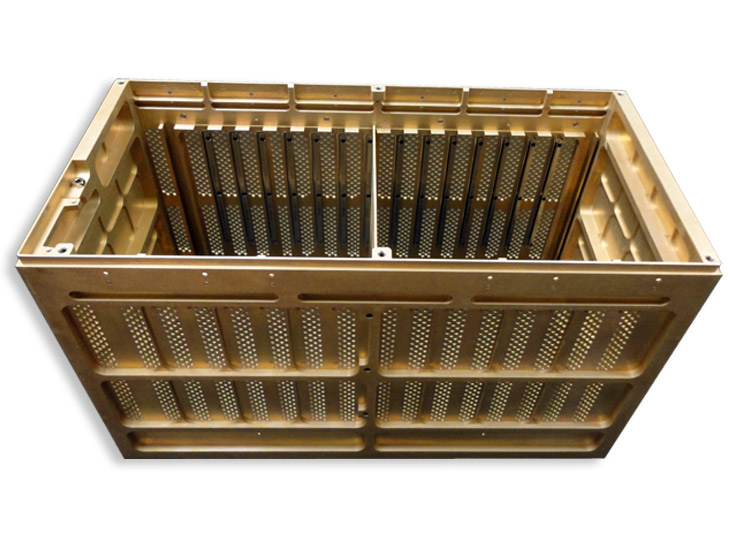

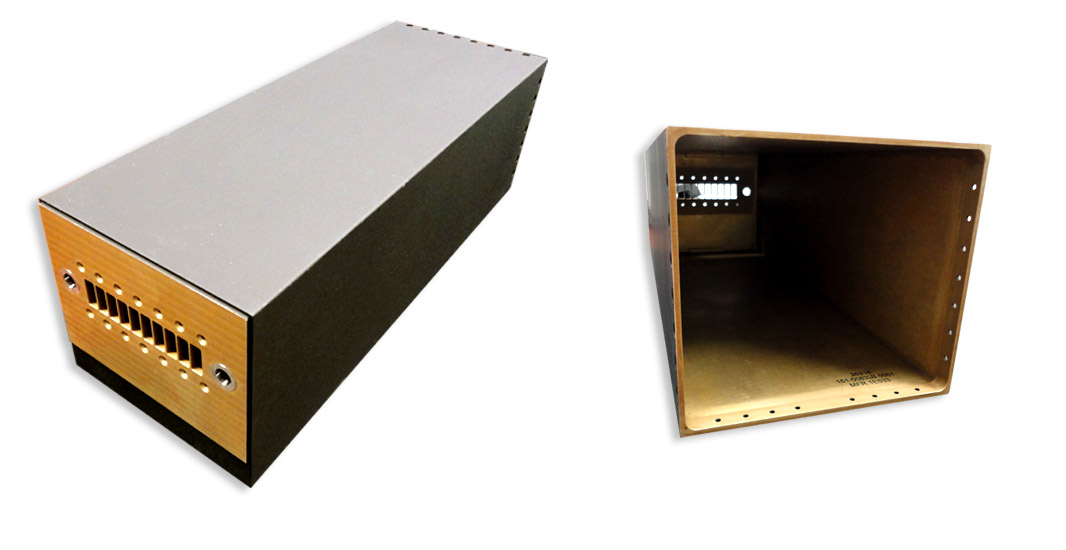

Aluminum Dip Brazing is a low cost process and usually requires little or no tooling charges. In the Dip Brazing process the filler metal melts and flows into the all the joints through a capillary action which creates leak proof joints. Brazed joints are unaltered by typical changes in temperature; minimize distortion and resists vibration and shock separation, unlike conventional welded joints. G&Z is capable of working with all grades of aluminum alloys.

Dip Brazing Services G&Z commonly provides:

- Machining of piece parts

- Mock up assembly of components prior to braze

- Coordinate Dip Braze process with NADCAP suppliers

- Sizing of the Brazement

- Post-Braze machining operations

- Coordination of Outside Processes (Chemical Film, Paint)

- Just-In-Time Delivery of finished product